The Cost of Choosing the Wrong Freight Forwarder (A Real Business Scenario)

In 2024, a mid-sized electronics distributor decided to cut logistics costs.

They chose a freight forwarder offering rates 18% cheaper than competitors.

On paper, it looked like smart business.

In reality, it nearly destroyed their expansion plans.

The Situation

- 2 containers of high-value electronics

- Shipment from Asia to West Africa

- Tight delivery deadline for a major retail contract

- Payment terms tied to on-time delivery

Everything depended on timing.

What Went Wrong

1️⃣ No Industry Experience

The forwarder had handled general cargo — not sensitive electronics.

Result:

- Poor packaging supervision

- Improper moisture control

- Minor water damage during transit

Losses started before arrival.

2️⃣ Weak Customs Handling

Documentation errors triggered inspection.

Inspection caused:

- 9-day delay

- Storage charges

- Demurrage fees

Retail partner penalties activated.

3️⃣ No Contingency Plan

When the vessel was delayed:

- No proactive communication

- No alternative routing

- No escalation structure

The business owner found out from the port agent — not the forwarder.

Trust collapsed instantly.

4️⃣ Hidden Charges Surfaced

The “cheap quote” excluded:

- Terminal handling

- Documentation amendments

- Extended storage

- Port congestion surcharge

Final logistics cost exceeded the original “expensive” competitors.

The Financial Impact

- Direct cargo damage

- Contract penalty fees

- Emergency local air shipment for partial stock

- Lost retailer confidence

- Reputation damage

Total impact: Over 3x the initial savings they thought they were making.

The Turning Point

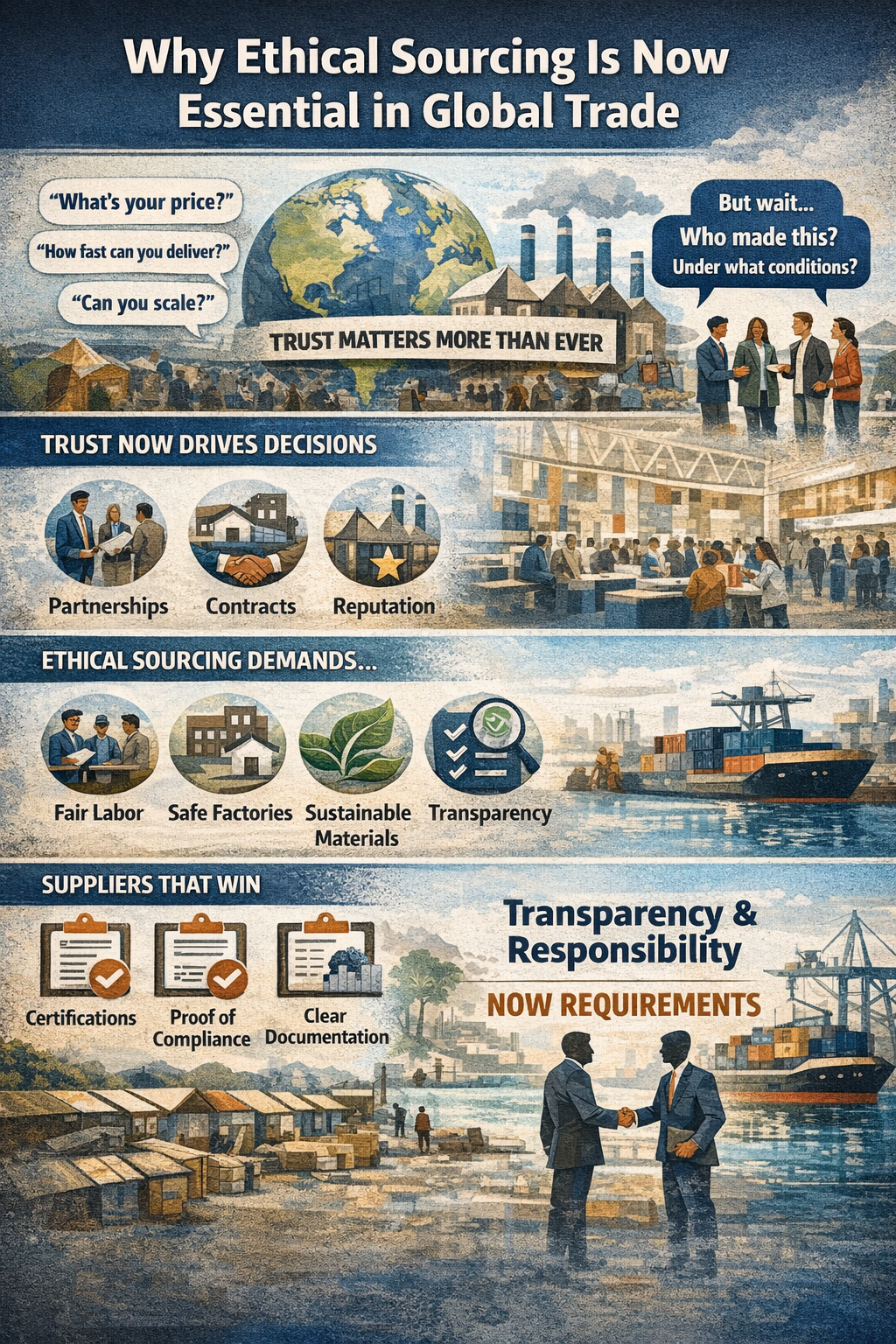

After the incident, the company restructured its freight selection process.

They implemented:

- Structured vetting checklist

- Mandatory license verification

- Industry specialization requirement

- Clear insurance review

- Technology-based tracking requirement

- Written cost breakdown policy

Logistics shifted from “price-based decision” to “risk-managed partnership.”

The Outcome

- Delivery reliability improved

- Retail confidence restored

- Hidden costs eliminated

- Insurance claims properly managed

- Profit margins stabilized

The lesson was expensive — but transformational.

The Real Takeaway

Freight forwarding is not a cost center.

It is a risk management function.

The cheapest forwarder often becomes the most expensive decision.

In Post 4, we will break down a practical framework you can use immediately to evaluate and select the right freight partner — step by step.